Exceptionally Flexible & Versatile – entrust your production management to Praxis ERP for a modern approach to manufacturing excellence.

Set of Benefits

Fully Integrated & Extensive

Operational Flexibility

Streamlined Processes

Batch & Job Control

Quality Improvements

Complete Traceability

Set of Features

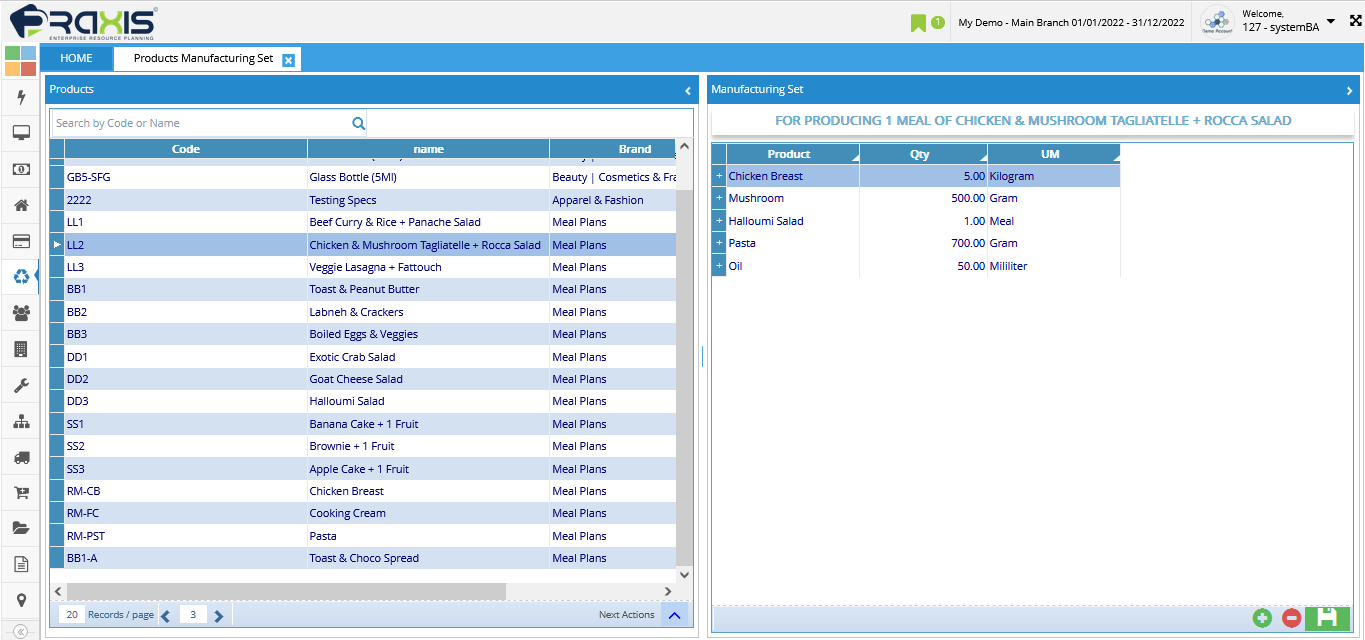

Managing complex production recipes has never been easier. With Praxis ERP, you can seamlessly create your default manufacturing sets using the needed raw materials, add/modify quantities, replace ingredients, and store mixed units of measure in order to produce the final product — hassle-free!

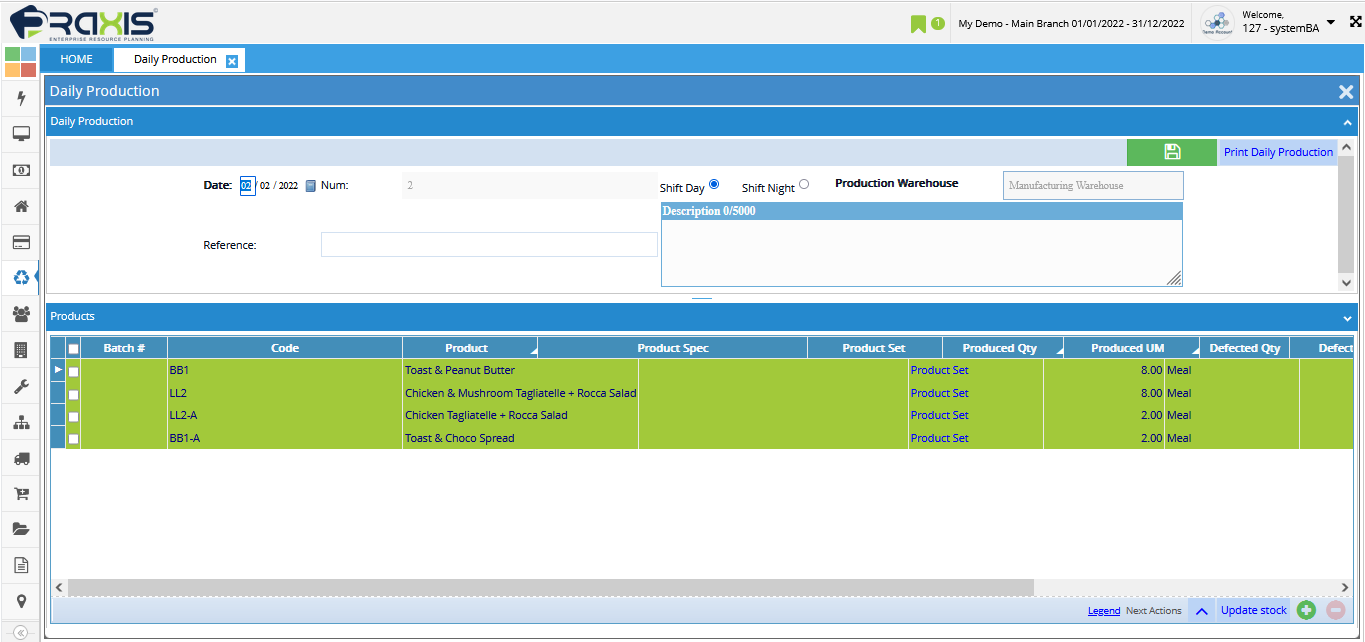

Take full control of your daily production and maximize production performance. Praxis ERP allows you to compare the default recipes against the actual total produced quantities and manage waste. You may then, flexibly adjust recipes and eliminate defects.

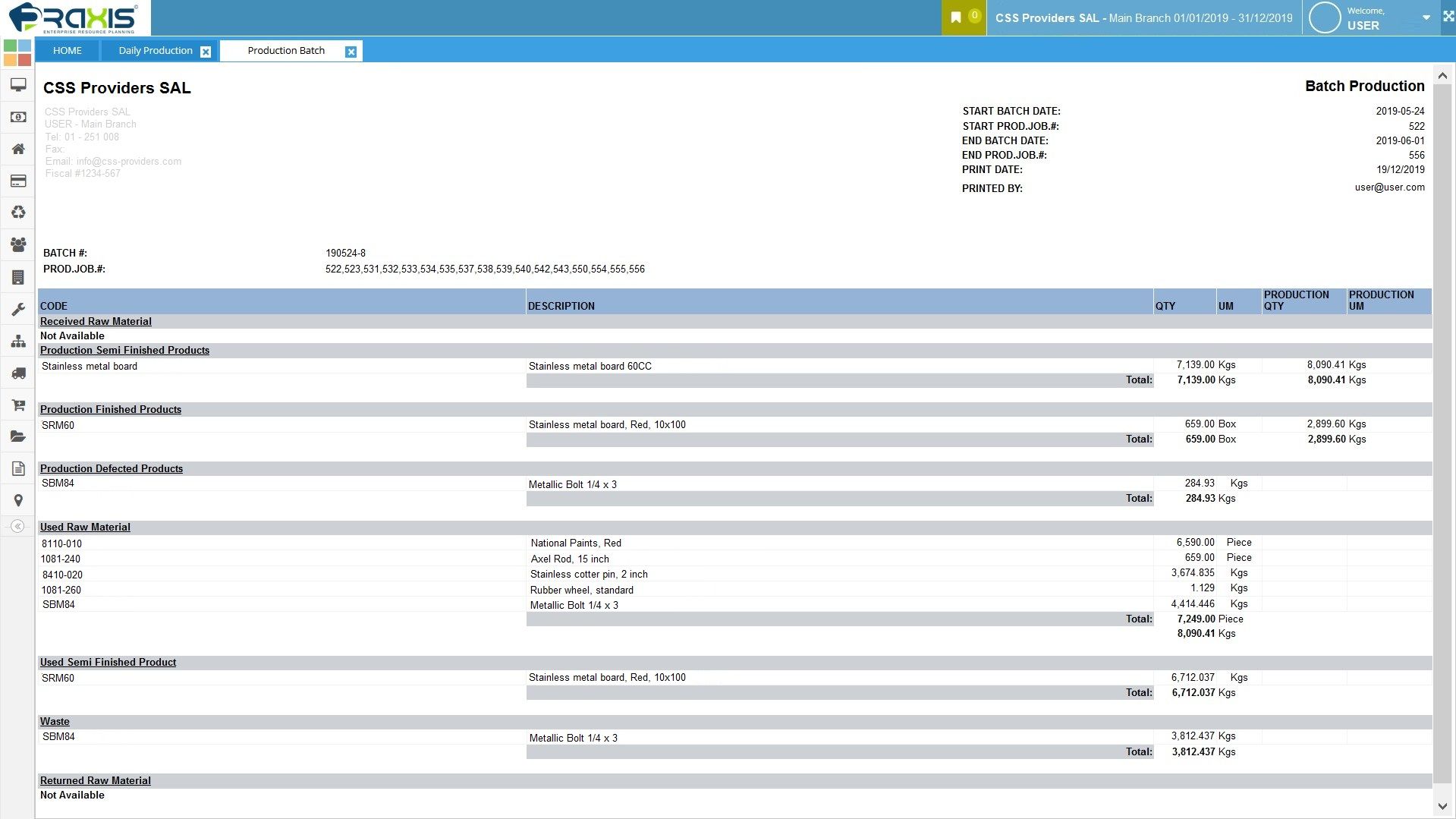

Consistent product quality is a key ingredient in customer satisfaction. Praxis ERP ensures an end-to-end batch and job control and allows you to track and trace all production activities with transparent traceability across batch/job numbers, product manufacturing sets, and periods.

Automating key processes is essential to saving time and increasing efficiency. After selling a manufactured product from the Point of Sale, Praxis ERP automatically creates a production job containing the pre-defined standard manufacturing set/recipe of that product that will then, automatically be reduced from stock.

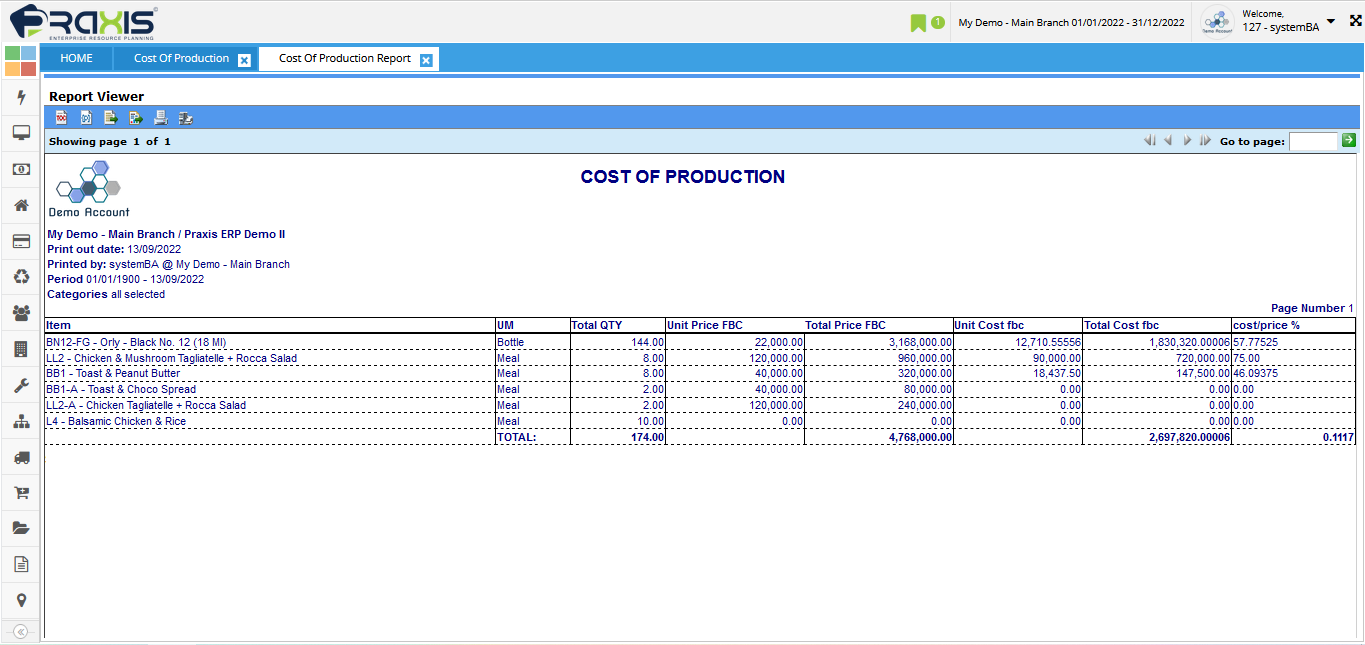

Gain valuable insights into your production costs in order to set smart pricing strategies and remain competitive. Praxis ERP tracks all costs of a manufactured product including material, labor, equipment, and other resources, giving you detailed analysis and reporting tools to help you identify the true operational costs and profit and continuously detect cost-reduction opportunities.

Praxis ERP helps you efficiently track all raw materials used during manufacturing processes while giving you access to crucial information for greater transparency and traceability. Defects in a batch of raw materials can be easily traced directly to their finished products, inefficiencies generated due to excessive raw materials usage may be quickly identified, and waste can be properly managed to improve overall profitability.

Home

Home